Polar Design Studio offers a highly successful business model to generate renewable electricity from anaerobic digesters at dairy farms, food and vegetable processing plants, bakery product plants, sugar waste and municipal waste plants. Our model provides a long term waste and waste effluent management system, prevents local pollution and reduces global warming emissions. Biogas is a mixture of Methane and CO2 and is produced from the decomposition of organic matter.

Convert your organic waste, and effluent disposal problem into a profitable business enterprise by generating the following commodities for use/sale:

- Renewable electricity

- Hot water and steam

- Fertilizer/bio-solids

- Carbon dioxide offsets and Renewable energy credits

Our model from concept to final project, was implemented at the Dane County Manure Handling Facility (GL Dairy Biogas Project) now owned and operated by Gunderson Health Systems, Wisconsin to reduce it’s healthcare facilities carbon footprint. A project conceived in collaboration with three large Wisconsin farms. www.gundersenenvision.org

Generates revenue from renewable electricity and thermal heat, generates revenue from carbon offsets, reduce expenditure spent on organic waste and effluent waste management and disposal.

By turning a waste liability into a profitable business generate revenues to reduce the impact of increasing commodity prices on your business and diversify income. The anaerobic digester waste to energy plants will bring an additional source of revenue through highly valuable carbon credits and renewable energy, at the same time reducing the impact of global warming.

Anaerobic Bio-digester Plant Types

Compressed Natural Gas (CNG) Bio-digester Plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- CNG processing & filling station

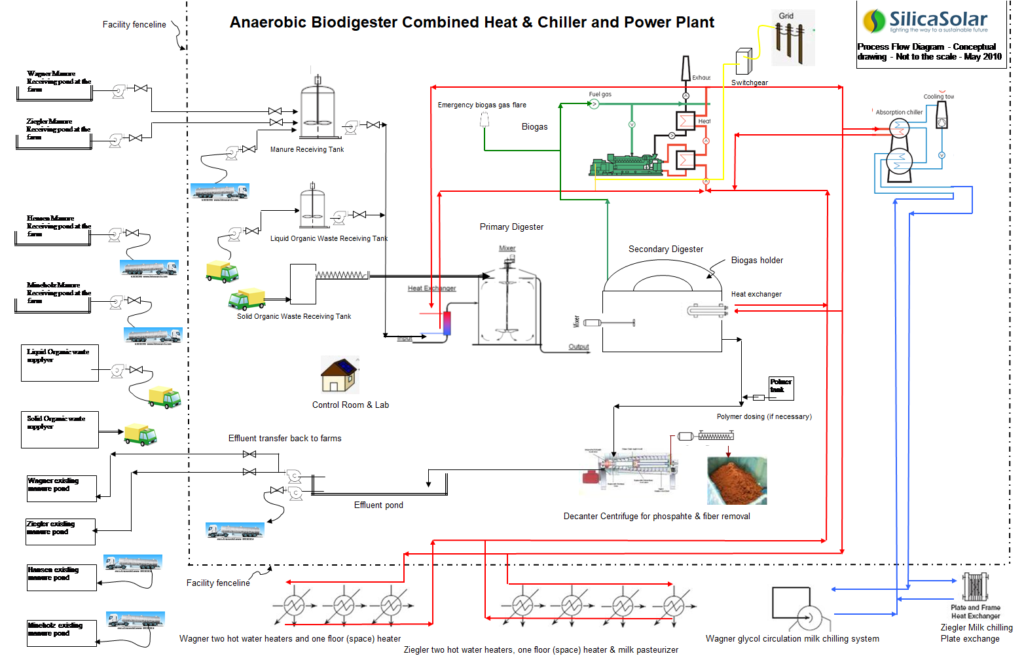

Combined Heat & Power (CHP) Bio-digester plant main Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat (steam/hot water) generation

Tri-generation (electricity, heat & cooling) Bio-digester plant Sections

- Bio-waste receiving and processing

- Bio-digester plant and Bio-digester Effluent Processing & Handling

- Power and heat, steam/hot water/chiller cooling for cold storage

- Electricity for Tube Wells

Contact us at: information@polardesignstudio.com or call us at 1-519-513-2020