At Polar Design Studio we can provide an in depth analysis and feasibility of bio gas project. We can take you through the steps from conceptual design, financial analysis to implementation. We can guide on the different bio digestor technologies and the one most suited to your project needs.

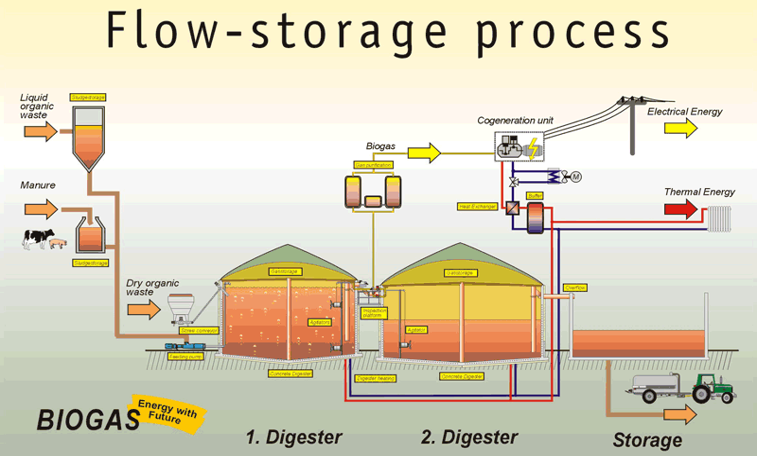

Agricultural and industrial, one and two stage mesophilic and thermophilic wet and dry fermentation plants; biogas plants for fermentation of cattle, pig, poultry manure, co-fermentation and bio-waste fermentation plants. The fermentation of wide range of substrates from grass silage, corn silage, bio-waste, manure, fats, kitchen wastes and many other organic wastes are part of spectrum. We can provide complete technology services from, planning, detailed engineering, construction supervision, commissioning, training, guarantee testing and after service technical support to optimize plant operation, maintenance for maximizing return on investment.

Application of Biogas Plants

- Agriculture & Dairy Industry

- Municipal Sewerage Treatment Plants

- Food Processing Industry

Organic Waste Substrates

- Dairy and poultry Farm waste

- Ghee, Fats and vegetable oil waste

- Organic sludge

- Kitchen, confectionary & restaurant waste

- Silages ( Corn, peas, grass)

- Food processing waste

- Sugar cane industry waste

- Slaughter house waste

Biogas Combined Heat & Power (CHP) Plant

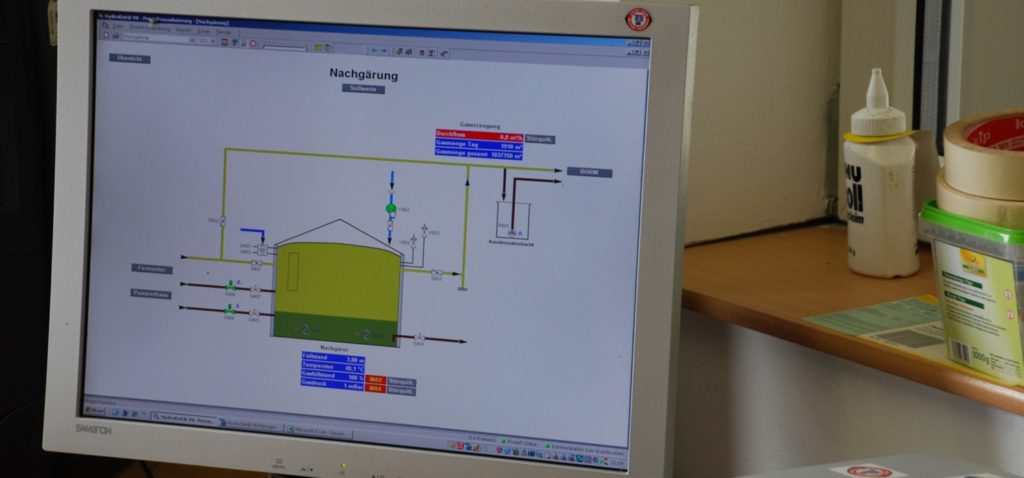

Anaerobic Bio-digester Technologies

High upright digester, central agitator

- Optimum mixing, constant gas production rate

- Good heat input, low heat losses

- Established for large scale plants

Flat digester, side mounted mixer

- Not optimum mixing, heat loses higher, moderate heat input

- Best suited for medium size waste digestion plant

- Less expensive compared to upright digester, low dry matter content

Plug flow digester, stirrer paddle

- High matter content possible, optimum mixing,

- expensive, not much experience in large scale plants

Products Obtained from the Bio-digester Plant

- Electricity Generation

- Waste heat recovery for steam and hot water

- Compressed natural gas (CNG) generation

- High quality solid fertilizer that can be bagged and sold separately

- Liquid fertilizer with soluble inorganic nitrogen for agricultural

- Carbon Emission Reduction (CERs) from CDM PDD

- Boosting green image of the company & making it sustainable